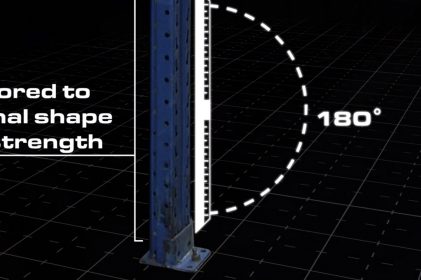

The basic principle of the ROS Rack Repair System is simple but effective: a mould is fitted to a damaged upright before a hydraulic tool exerts controlled pressure to return the upright to its original form. The patented process is completed in a matter of minutes. Even quite severely deformed uprights can be successfully repaired using the ROS system. However, if there is a break or tear in the metal of the damaged upright, safe repair will not be possible, and the ROS technicians will always recommend replacing it in such circumstances.